Powder Coating OKC

Professional Powder Coating

Powder coating OKC – locally owned and operated, Precision Metal Forming provides powder coating services locally throughout the Oklahoma City metro area and servicing the entire state. Since 1982 we have provided a wide variety of custom design, fabrication and powder coating services to customers in Oklahoma and nationwide.

With our conveyorized powder coatings line, we can apply a long lasting powder coating finish of your choice. We take pride in offering the best possible design, prototype, manufacturing, and powder coated finish customized for your needs.

For powder coating OKC and throughout Oklahoma, we offer the benefits of over 40 years of experience. We offer a full line of professional wire forming and powder coating applications. Our full-service custom metal fabrication and powder coating services give you a wide range of selections to fit any size project.

Precision Metal Forming provides high quality products that meets our customer’s specifications, with custom design, custom wire forming, sandblasting, and fluidized sand bed paint removal and a prestige powder coat finish.

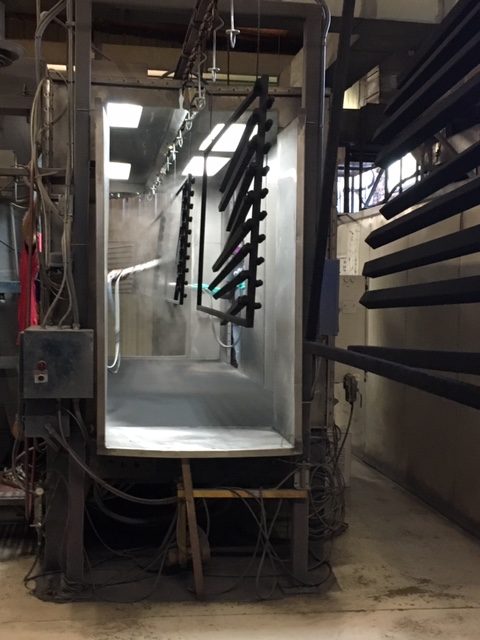

Powder Coating Process

The powder coating process is the most durable finish for metal substrates. Powder coating provides the best outstanding protective finish that withstands exposure to the elements of weather, chemicals and a variety of abuse. Plus, there is a wide variety of choices: COLOR, TEXTURES, SHEENS.

To ensure the finish looks as nice as possible. We start the powder coating process for your product on our conveyor belt with a five-stage pre-treatment system.

In addition, products are painted and placed in an oven where the powder is baked at precise temperatures.

Once completed, your product has a durable finish with a reduced risk of chipping or fading.

Precision Metal Forming, LLC is centrally located in Oklahoma City, Oklahoma. Find us on google maps.

Furthermore, all our powder coating projects utilize the highest quality powders, with a long-lasting finish provided by top powder manufacturers in the industry. We perform a wide variety of tests to insure our consistent quality.

Learn more about our Oklahoma Powder Coating services.

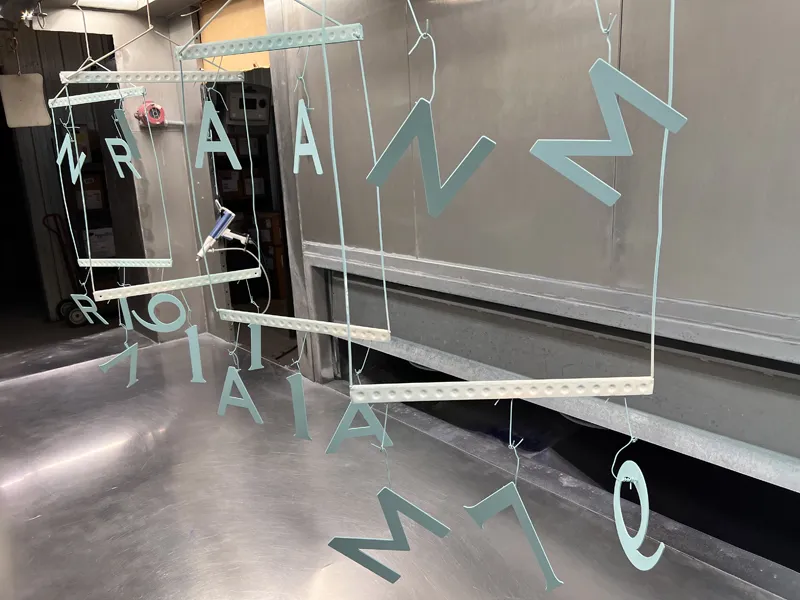

Fluidized Sand Bed Stripping

Fluidized sand bed stripping is a method in removing cured powder coatings.

The process uses an inert media (sand or oxides) that are used as a heat transfer medium.

In sand bed system, natural gas and air are forced through the medium and are ignited at the surface of the medium. This transfer of heat fluidizes the medium. The product with the cured powder coatings is then lowered into the tank of fluidized medium at a temperature of approximately 800F.

The medium begins breaking down the powder coating on the the product and the agitation of the fluidized medium removes any ash on the product. The normal time frame for the product to be in the tank is relatively fast – about 30-60 minutes.

- There is no damage to parts because the heat is dispersed equally in the tank.

- Products cleaned in this method require minimal cleaning efforts to be prepared for the recoating process.

- The fluidized sand bed stripping method is safe and environmentally friendly.

- There are no toxic chemicals used or hazardous waste generated.

In conclusion, Precision Metal Forming provides professional services to meet and exceed customer expectations.

Powder Coating OKC